Process Film on Semiconductor, Electronic Parts

Cover Tape(Tape & Reel) for packaging the electronic parts

Force-One's is uniquely designed to peel through the film itself and available as static dissipative.The cover tapes for semiconductor(IC) or Passive components seal electrical and electronic components into Carrier Tapes during transport and storage. The cover tapes for semiconductor could combine excellent sealing properties with smooth peel force to protect IC or Passive components and permit efficient pick-and-place operations. The full line of Force-One's Cover Tapes includes conductive, non-conductive and static dissipative products with heat activated or pressure-sensitive adhesive.

The cover tapes(Tape & Reel) for semiconductor(IC) or Passive components is good for SMD/SMT(Surface-Mount Device / Surface-Mount Technology) process. And can anti-static cover tape for packaging of surface mount devices (ESD protection).

Common TDS: Thin:0.05~0.06 mm ; Transmittance: 60%~89% ; Haze: 3%~30% ; Anti-static: ≦10^9-11Ω/sq ; Working temperature:140℃ - 190℃ ; RA pass:55℃~60℃/720 hrs

◆Heat Activated (HAA)

1. Normal Type

2. Transparent Type

3. Conductive Type

◆Pressure Sensitive Adhesives Sensitive (PSAs)

1. Normal Type

2. Conductive Type

3. Heat-Resisting Type

Want to know more, Welcome to Contact us

---Thermal Release Tape---

The thermal Release Film is a special adhesive tape which is mainly composed of a layer of adhesive on a substrate. The substrate used is a plastic film, and the adhesive is a pressure-sensitive adhesive which has a reduced peeling force after being heated to a certain temperature, and can be released the components after being heated to a proper temperature after the process is completed. Applied for stacking, cutting, flipping of multilayer ceramic capacitors (MLCC) or other components. Especially in the work that can not be achieved by the UV release tape, it can often be done by thermal Release Tape. We still can customized development according to request.

1. After heating, the peeling force of adhesion is very low, and no residue left after removal.

2. The reaction time is fast after heating, which can effectively improves work efficiency.

3. Special adhesive formula, good adhesion, no scattering when cutting.

4. Special structural design to reduce the impact on the life of the cutting knife.

Specification:

1. Low temperature: 90-100 degrees, 3-5 minutes foam stripping

2. Medium temperature: 120-130 degrees, 3-5 minutes foam stripping

3. High temperature: 140-150 degrees, 3-5 minutes foam stripping

4. Ultra high temperature: 160-170 degrees, 3-5 minutes foam stripping

Know About*Thermal Release Tape

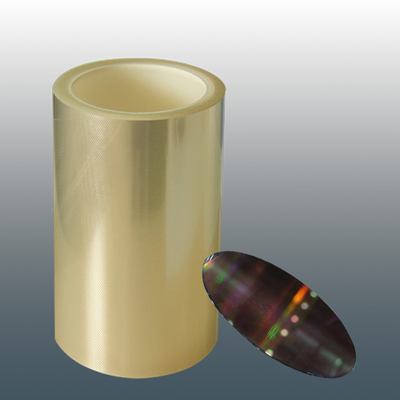

---UV Cure Release Film---

Coating UV cure release adhesive on PET film or other optical film. The adhesion of UV cure release adhesive before UV curing can be adjusted from 500g to 2500g. After UV curing, the adhesion can be reduced to less than 30g.

UV cure release tape is applied to: glass cutting protection, polishing, grinding, developing, cutting process, small area copper foil and PCB cutting process.

UV release film product features:

1. After UV curing, the adhesion is very low, and no residue left after removal.

2. Have quick UV reaction time, it can improving efficiency.

3. Before UV curing it has good and reliable adhesion, to protect when cutting.

4. Special structural design to reduce the impact on the life of the cutting knife.

Know About*UV Release Tape

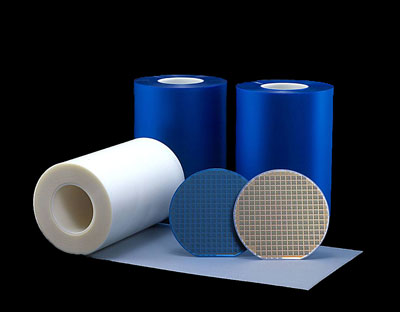

---High Temperature Resistance Back-Grind Tape---

Force-One's Backgrind tapes are designed for surface protection of semiconductor wafers during backgrinding or cutting process. It has high temperature resistance, can be removed by cleaning with pure water and no danger of contamination from cleaning fluids.

The benefit of back grind tape:

1.Fully protects the wafer surface during back grinding and prevents wafer surface contamination from infiltration of grinding fluid and/or debris

2.There is virtually no residual adhesive after tape is peeled off.

3.For cases in which slight contamination remains because of wafer surface configuration, the line-up includes a type that can be removed by cleaning with pure water.

Additionally, there is no danger of contamination from cleaning fluids because there are no water-soluble ingredients of light molecular weight in the adhesive.

4.High precision tape thickness accuracy ensures precision wafer thickness after back grinding.

Know About*Back-Grind Tape