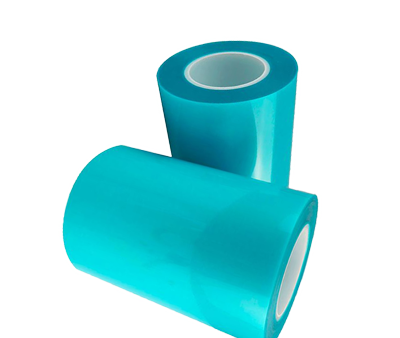

Thermal Release Film

---Thermal Release Tape---

Thermal Release Film or Dicing Tape, Valfo Tape can be released after heating the tape to a specific temperature. So it can be applied on somewhere which you want to protect or fix your products, but need quick to release by heating. The thermal Release Film is a special adhesive tape which is mainly composed of a layer of adhesive on a substrate. The substrate used is a plastic film, and the adhesive is a pressure-sensitive adhesive which has a reduced peeling force after being heated to a certain temperature, and can be released the components after being heated to a proper temperature after the process is completed. Applied for stacking, cutting, flipping of multilayer ceramic capacitors (MLCC) or other components. Especially in the work that can not be achieved by the UV release tape, it can often be done by thermal Release Tape. We still can customized development according to request.

1. After heating, the peeling force of adhesion is very low, and no residue left after removal.

2. The reaction time is fast after heating, which can effectively improves work efficiency.

3. Special adhesive formula, good adhesion, no scattering when cutting.

4. Special structural design to reduce the impact on the life of the cutting knife.

Specification:

1. Low temperature: 90-120 degrees, 3-5 minutes foam stripping

2. Medium temperature: 140-150 degrees, 3-5 minutes foam stripping

3. High temperature: 180-190 degrees, 3-5 minutes foam stripping

4. Ultra high temperature: 230-240 degrees, 3-5 minutes foam stripping

Thermal Release Tape provides a variety of applications that include the risk of reducing residual glue in high temperature processes and reducing the Peel force problem, thereby increasing the efficiency of line rework for faster productivity.

It is applied to various temporary adhesive fixing processes. After the processing process or semi-finished products are finished, the film is removed by heating. The product is suitable for a wide range of industries, such as wafer, glass, ceramic, grinding/polishing/cutting or The printing industry and other processes are used.

Application:

1. Electronic and optoelectronic industry industrial process production and processing use as below:

a. LCD screen or touch panel glass grinding and polishing, LED cutting and polishing, MLCC cutting, diode, inductor, semiconductor solid-carrying chip, etc. The wafer is temporarily fixed for grinding, cutting, fixing, and heating. Fix and protect the Chip circuit or board surface from scratches

b. The touch panel process adheres between the glass and the glass. During the process, it is heated twice by the oven (closed Chamber), and sprayed or soaked in the middle of the two ovens through KOH (alkaline) and DIW.

2. LED sapphire substrate thinning polishing process replaces polishing and waxing process

3. Four-dimensional LED Silicon wafer thinning process, the tape can be applied to the four-dimensional thinning process of LED Silicon wafer to protect the wafer itself and reduce the fragmentation caused by the generated micro-particles during processing.

4. Copper substrate graphene transfer or carbon nanotube transfer process.

We still have other release film like UV release film, you can check it to know more.