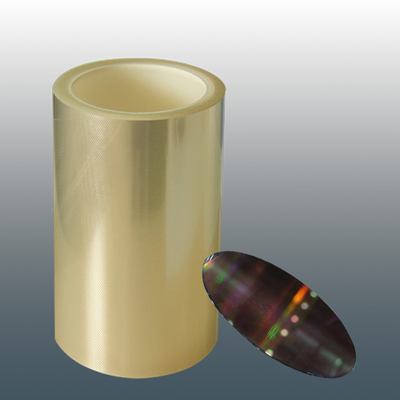

UV Release Film

---UV Cure Release Film---

UV Release Film(Dicing tape) can be released after UV curing the tape from a specific UV wavelength. So it can be applied on somewhere which you want to protect or fix your products, but need quick to release by UV curing. Coating UV cure release adhesive on PET film or other optical film. The adhesion of UV cure release adhesive before UV curing can be adjusted from 500g to 2500g. After UV curing, the adhesion can be reduced to less than 30g.

UV cure release tape is applied to: glass cutting protection, polishing, grinding, developing, cutting process, small area copper foil and PCB cutting process.

UV release film product features:

1. After UV curing, the adhesion is very low, and no residue left after removal.

2. Have quick UV reaction time, it can improving efficiency.

3. Before UV curing it has good and reliable adhesion, to protect when cutting.

4. Special structural design to reduce the impact on the life of the cutting knife.

UV cure release tape (Dicing tape) is a kind of pressure-sensitive adhesive tape, which is mainly composed of a layer of adhesive coated on a substrate. The substrate used is a plastic film, the common substrate is PO (Polyolefin), PVC and PET; and the adhesive is a kind of pressure-sensitive adhesive with a reduced adhesion after UV reaction, and the adhesive has high adhesion before UV reaction. However. After the ultraviolet ray is irradiated, the polymer chain is formed into a three-dimensional network structure, which is also called a UV-curable pressure-sensitive adhesive, and the adhesion is sharply lowered by hardening, which can be easily and cleanly stripped.

This tape used in manufacturing component-embeded substrates,which can temporarily fix components at high temperatures and be removed by UV irradiation. UV cure release tape can be applied to wafer grinding and cutting, ceramic material passive components and LED heat sink substrate ceramic wafer cutting process, glass substrate polishing and cutting process, so that the wafer and other components do not fall off during the grinding and cutting process. Scattered and exposed to UV light after processing, the tape can be easily stripped from the workpiece; or during the manufacture, storage, and transportation of semiconductor wafers, the UV tape can temporarily protect the wafer surface from scratches and damage. UV tapes can be divided into two types of applications, such as Back Grinding and Dicing, in semiconductor packaging applications to speed up the process and increase the utilization rate.

We still have other release film like thermal release film, you can check it to know more.