Biomass Plastics Film

◆Biomass Plastics Film

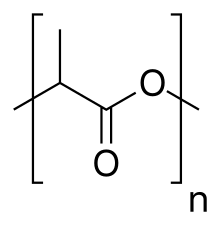

Poly(lactic acid) or polylactic acid or polylactide (PLA) is a biodegradable and bioactive thermoplastic aliphatic polyester derived from renewable resources, such as corn starch , cassava roots, chips or starch , or sugarcane.

Force-One Applied Materials INC. want to use the green technology to make world better. So we develop PLA for anything you want, like food packing, medical packing, cup. Even if plastic products still not totally be replaced, but we still hope can reduced using plastic product.

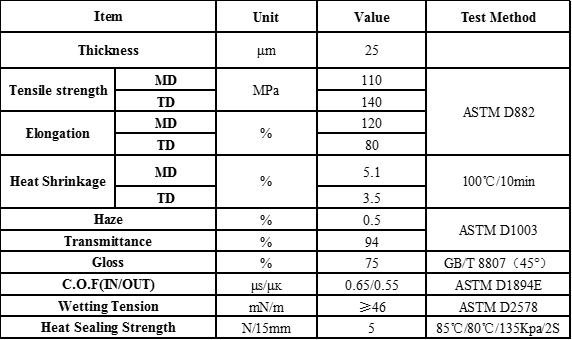

As blow SPEC is Force-One Applied Materials INC. product PLA's SPEC, we still have other products of PLA . If you have any help, welcome to feel free to Contact Us.

What is Biomass Plastics Film

Bioplastics are plastics derived from renewable biomass sources, such as vegetable fats and oils, corn starch, or microbiota. Bioplastic can be made from agricultural by-products and also from used plastic bottles and other containers using microorganisms. Common plastics, such as fossil-fuel plastics (also called petrobased polymers) are derived from petroleum or natural gas. Production of such plastics tends to require more fossil fuels and to produce more greenhouse gases than the production of biobased polymers (bioplastics).Not all bioplastics are biodegrade nor biodegrade more readily than commodity fossil-fuel derived plastics. Bioplastics are usually derived from sugar derivatives, including starch, cellulose, lactic acid. As of 2014, bioplastics represented approximately 0.2% of the global polymer market (300 million tons).

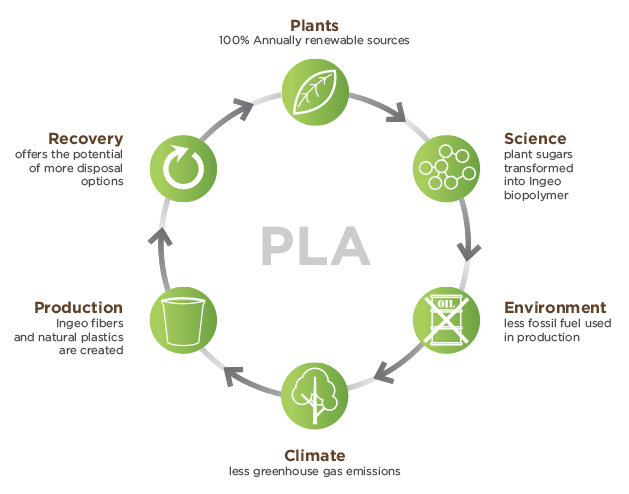

Biomass plastics utilize the biomass resources of regenerable biological origin. Currently, biomass plastics based on plant-derived materials are in practical use. The plastics are high-polymer materials made of raw materials consisting of starch, sugar, or cellulose contained in plants. One example is polylactic acid, the chemically-synthesized lactic acid that is fermented from starch. Even if CO2 is ejected when polylactic acid is incinerated, it is utilized in photosynthesis by growing plants that are used as materials; the CO2 in the atmosphere does not increase (carbon-neutral). Therefore, it is an environmentally-friendly material that does not contribute to global warming (Figure 1). Furthermore, this material is as strong and rigid as polystyrene. However, for polylactic acid to be used as a material in durable goods, issues related to heat resistance and impact resistance as well as flame retardancy need to be addressed; the material must provide non-flammable parts for electric and electronic devices. Furthermore, issues related to molding techniques for mass production of components have to be addressed.

Poly(lactic acid) or polylactic acid or polylactide (PLA) is a biodegradable and bioactive thermoplastic aliphatic polyester derived from renewable resources, such as corn starch (in the United States and Canada), cassava roots, chips or starch (mostly in Asia), or sugarcane (in the rest of the world). In 2010, PLA had the second highest consumption volume of any bioplastic of the world.

The Introduction of Film Capacitor is from://en.wikipedia.org/wiki/Polylactic_acid