PET Film (Polyethylene Terephthalate)

◆Difference Glue

1. Pressure Sensitive Adhesive PF

2. PU Adhesive PF

3. Silica Adhesive PF

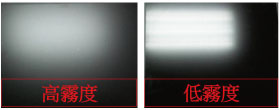

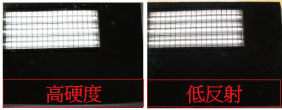

◆Difference Surface

1. High Haze Surface

2. Low Haze Surface

3. Hard Coating Surface

4. Low Reflection Surface

From left to right: Haze:30 / Haze:8 / Hard Coating / Hard Coating Low Reflection / Hard Coating Anti-Reflection

◆Special Function

1. UV cut

2. IR cut

3. Anti Static

4. Anti Finger

◆Customized Protective Film

What is BoPET?

BoPET (Biaxially-oriented polyethylene terephthalate) is a polyester film made from stretched polyethylene terephthalate (PET) and is used for its high tensile strength, chemical and dimensional stability, transparency, reflectivity, gas and aroma barrier properties, and electrical insulation.

A variety of companies manufacture boPET and other polyester films under different brand names. In the UK and US, the most well-known trade names are Mylar, Melinex, and Hostaphan.

Manufacture and properties

The manufacturing process begins with a film of molten polyethylene terephthalate (PET) being extruded onto a chill roll, which quenches it into the amorphous state.[5] It is then biaxially oriented by drawing. The most common way of doing this is the sequential process, in which the film is first drawn in the machine direction using heated rollers and subsequently drawn in the transverse direction, i.e. orthogonally to the direction of travel, in a heated oven. It is also possible to draw the film in both directions simultaneously, although the equipment required for this is somewhat more elaborate. Draw ratios are typically around 3 to 4 in each direction.

Once the drawing is completed, the film is "heat set" or crystallized under tension in the oven at temperatures typically above 200 °C (392 °F). The heat setting step prevents the film from shrinking back to its original unstretched shape and locks in the molecular orientation in the film plane. The orientation of the polymer chains is responsible for the high strength and stiffness of biaxially oriented PET film, which has a typical Young's modulus of about 4 GPa. Another important consequence of the molecular orientation is that it induces the formation of many crystal nuclei. The crystallites that grow rapidly reach the boundary of the neighboring crystallite and remain smaller than the wavelength of visible light. As a result, biaxially oriented PET film has excellent clarity, despite its semicrystalline structure.

Applications

Flexible packaging and food contact applications

Covering over paper

Insulating material

Solar, marine and aviation applications

Electronic and acoustic applications

Graphic arts

What is BoPET? is from wikipedia